How to Choose the Right Motors and Control Systems for Your Projects?

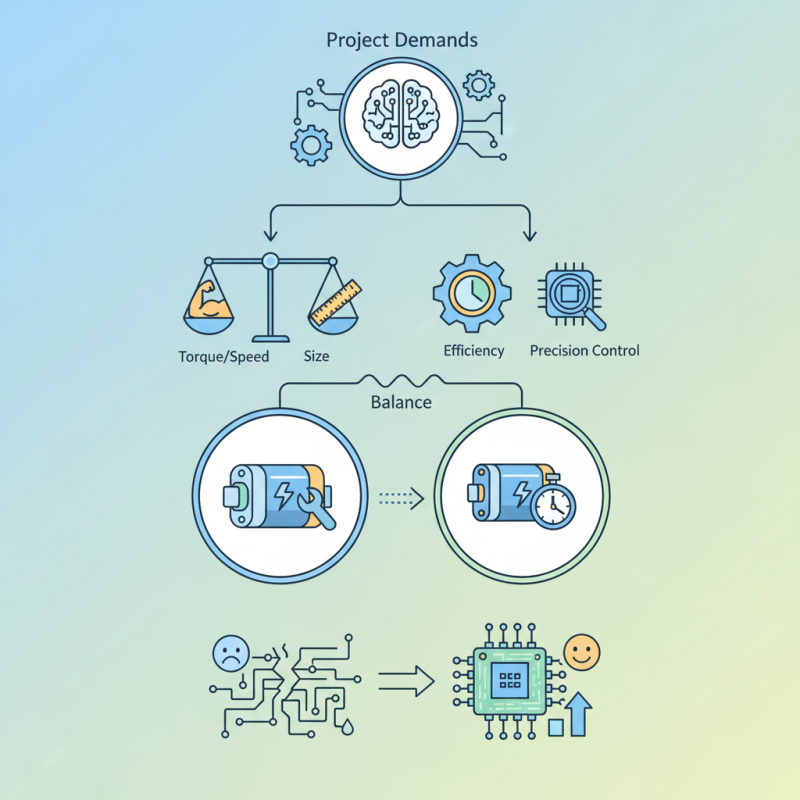

When tackling engineering and robotics projects, selecting the right motors and control systems is crucial. Each project has specific requirements, and not every motor fits. Factors to consider include torque, speed, and size. The choice of motors and control can affect your project’s overall performance. A small motor may lack the power needed, while a large one might be inefficient.

Understand the project’s demands before choosing. What are the load requirements? How precise must the control system be? Sometimes, the best option is not the most powerful one. A balance between performance and efficiency is essential. Consider the workspace dynamics too.

Getting it right can be challenging. Maybe you’ve had a project fail due to poor choices in motors and control systems. Reflecting on those experiences allows for growth. Each step in this process enhances your knowledge, leading to better decisions in future projects. A thoughtful approach ensures your projects not only function but excel.

Understanding Different Types of Motors and Their Functions

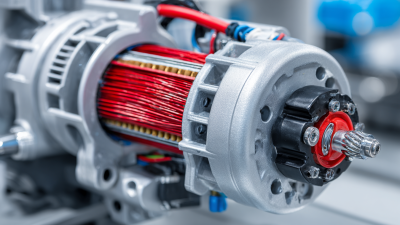

When selecting motors for projects, understanding motor types is crucial. DC motors are popular for their simplicity and ease of control. They deliver consistent torque and speed, making them suitable for applications like robotics and small appliances. Reports indicate that the global brushed DC motor market is projected to grow by over 6% annually.

Stepper motors are another option. They operate in precise steps, ideal for applications requiring exact positioning. Their ability to control movement without feedback systems is a game-changer in automation. However, they can lose steps under heavy loads. This reflects a need for careful planning in system design.

Brushless motors offer high efficiency and longevity. They achieve this by avoiding friction from brushes. Nevertheless, they require more complex drivers and control systems. Many projects might struggle with this complexity, leading to increased costs. Proper analysis is essential before integrating them into a design. Each motor type has its strengths and weaknesses. Understanding these can enhance performance and reliability in your projects.

How to Choose the Right Motors and Control Systems for Your Projects?

| Motor Type | Voltage (V) | Current (A) | Power (W) | Control Type | Applications |

|---|---|---|---|---|---|

| DC Motor | 12 | 1.5 | 18 | H-Bridge | Robots, Fans |

| Stepper Motor | 5 | 1.2 | 6 | Pulse Width Modulation | 3D Printers, CNC Machines |

| Servo Motor | 6 | 0.8 | 5 | PWM | Robotics, Automation |

| BLDC Motor | 24 | 2 | 48 | ESC (Electronic Speed Control) | Drones, Electric Vehicles |

| Induction Motor | 230 | 10 | 2300 | Variable Frequency Drive | Industrial Applications, Pumps |

Evaluating Power Requirements for Your Motor Selection

When evaluating power requirements for motor selection, start by defining the tasks the motor will perform. Consider the weight of the load and the desired speed. For instance, lifting a heavy object requires more power than simply moving it horizontally. Expect to calculate the torque needed at various speeds to ensure proper performance.

Next, assess the power supply available for your project. If using batteries, understand their voltage and current limitations. Motors can behave unpredictably if they operate outside these limits. Also, think about possible inefficiencies in your system. A motor that seems just powerful enough could struggle and cause overheating if not paired with the right control system.

Don't forget to check the duty cycle of your motor. Continuous operation demands higher power ratings than intermittent use. Sometimes, projects require motors to run for long durations. Be realistic about your cooling solutions. A motor that overheats frequently can lead to failures. It's essential to match all these elements to ensure a reliable operation.

Exploring Various Control Systems: Basics and Types

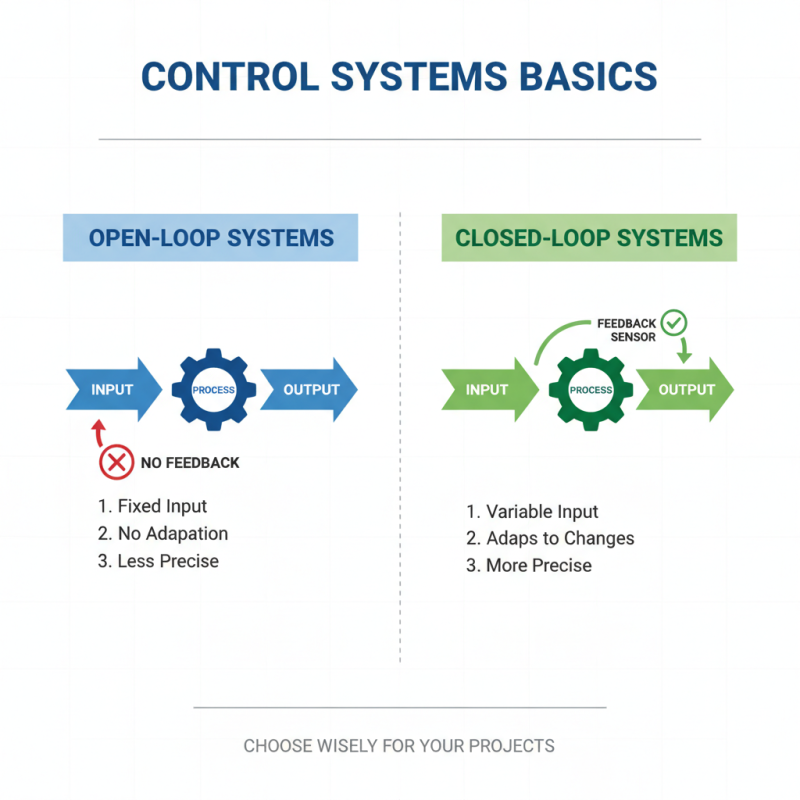

When selecting control systems for your projects, understanding the basics is crucial. Different types of control systems exist, each with unique features. Some are open-loop systems, which operate on a fixed input. They lack feedback and may not adapt to changes in conditions.

Closed-loop systems, on the other hand, utilize feedback. These systems can adjust their output based on measuring the actual performance. They tend to be more versatile. However, they can be complex and require careful calibration. Mistakes in tuning these systems can lead to inaccuracies.

Consider your project's specific needs. Sometimes, using an overly complex system complicates things unnecessarily. Simplicity can be more effective in certain applications. Evaluating your goals helps determine the right fit. Don't overlook the importance of testing different setups. Every project can teach valuable lessons in control system selection.

Matching Motors with Suitable Control Systems for Performance

Choosing the right motors and control systems can significantly impact project performance. Motors convert electrical energy to mechanical energy, influencing speed, torque, and efficiency. For instance, brushless DC motors often provide higher efficiency and longer lifespan than brushed counterparts. Reports show a potential 20% efficiency increase with proper motor selection.

Control systems are equally critical. They manage the motor's functions, ensuring precision and responsiveness. For example, PID controllers excel in maintaining desired performance levels. A study indicated that systems using advanced control strategies could improve response times by as much as 50%. However, the complexity of integration can lead to challenges. Engineers may struggle with tuning parameters for specific applications.

Matching the right motor with a compatible control system is essential yet often overlooked. Misalignment can lead to performance issues. An underpowered motor might not meet operational demands. Conversely, over-specifying can result in wasted resources. Engineers must balance performance and efficiency, considering factors like load characteristics and duty cycles. These decisions require careful thought and reflection on available data.

Assessing Budget Constraints and Future Project Scalability

When assessing budget constraints for motors and control systems, it’s essential to conduct a thorough evaluation. A recent industry report shows that 45% of project managers exceed their budgets due to insufficient planning. Key elements include initial costs, maintenance, and potential scalability. Higher initial investments in high-quality motors may lead to lower long-term expenses. It's a balancing act between upfront costs and future needs.

Future project scalability must also be considered. Data indicates that 60% of companies plan to expand their operations within the next five years. Investing in modular systems can allow for easy upgrades and expansions later. However, many teams overlook this factor, leading to costly retrofits later. It's vital to choose equipment that aligns with both current and potential needs without compromising on performance.

Additionally, consider that not all applications require top-tier components. Over-specifying can waste resources. Some projects may benefit from simpler systems that fit tighter budgets. Analyze the specific requirements of each project carefully and be prepared to adapt as necessary. Striking the right balance is critical to long-term project success.

Motor Types vs. Control Systems for Project Scalability

This chart presents a comparison of various motor types based on their costs, which can help in assessing budget constraints for your project. Understanding the differences in pricing can aid in making decisions about scalability for future projects.

Related Posts

-

Unlocking the Future: How Motors and Control Systems Propel Innovation in Technology

-

2025 How to Select the Right Motors and Control Systems for Your Project

-

Exploring the Future of Motor Control Solutions: Innovations That Drive Efficiency and Precision

-

How to Choose the Right Motor Control Solutions for Your Industrial Needs

-

10 Essential Tips for Understanding Motors and Control Systems Effectively

-

Understanding the Basics of Motor Control: How Your Brain Coordinates Movement