Top PCB Companies of 2025: What to Look for in Quality and Innovation?

In the rapidly evolving landscape of printed circuit boards (PCBs), identifying the top PCB companies of 2025 necessitates a keen understanding of quality and innovation. As the demands for more complex electronic devices continue to rise, it becomes imperative for industry players to not only keep pace with technological advancements but also to set benchmarks for quality assurance. Renowned PCB industry expert Dr. Emily Carter emphasizes the importance of this evolution, stating, "The future of the PCB industry hinges on companies that prioritize both innovative design and stringent quality control."

As we explore the top PCB companies poised to lead in 2025, it is essential to consider the attributes that mark excellence in this sector. Companies must leverage sophisticated manufacturing techniques, imbue sustainability practices into their processes, and ensure reliability in their products. Quality assurance and innovative approaches to design will distinguish the leaders from the rest. A thorough analysis of these factors will illuminate the traits we should anticipate in the PCB companies shaping the industry's future.

In summary, the PCB industry stands at a critical juncture as it embraces new challenges and opportunities. Companies that can intertwine quality with innovation will not only define their success but also set the standard for the entire sector. Understanding these dynamics will be crucial for stakeholders looking to invest or collaborate with top PCB firms in the coming years.

Top PCB Companies: An Overview of Industry Leaders for 2025

As the PCB industry continues to evolve, 2025 is set to showcase a new wave of innovative leaders that prioritize quality, sustainability, and technological advancement. Among the key trends is the increasing emphasis on environmentally friendly manufacturing processes. Companies are investing in sustainable materials and energy-efficient technologies, aligning with global initiatives to reduce their carbon footprint. This commitment to sustainability not only attracts eco-conscious consumers but also meets the regulatory demands of various markets.

In addition to sustainability, the focus on advanced technologies such as 5G, Internet of Things (IoT), and automotive applications is reshaping the landscape. Leading companies are leveraging state-of-the-art manufacturing techniques and automation to enhance precision and efficiency. Emphasis on research and development plays a crucial role, as firms strive to create innovative products that can cater to the growing complexities of high-frequency applications and miniaturization. As the competition intensifies, industry leaders will need to demonstrate their ability to adapt and push the boundaries of technology while maintaining stringent quality standards.

Key Factors in Assessing PCB Quality and Performance Metrics

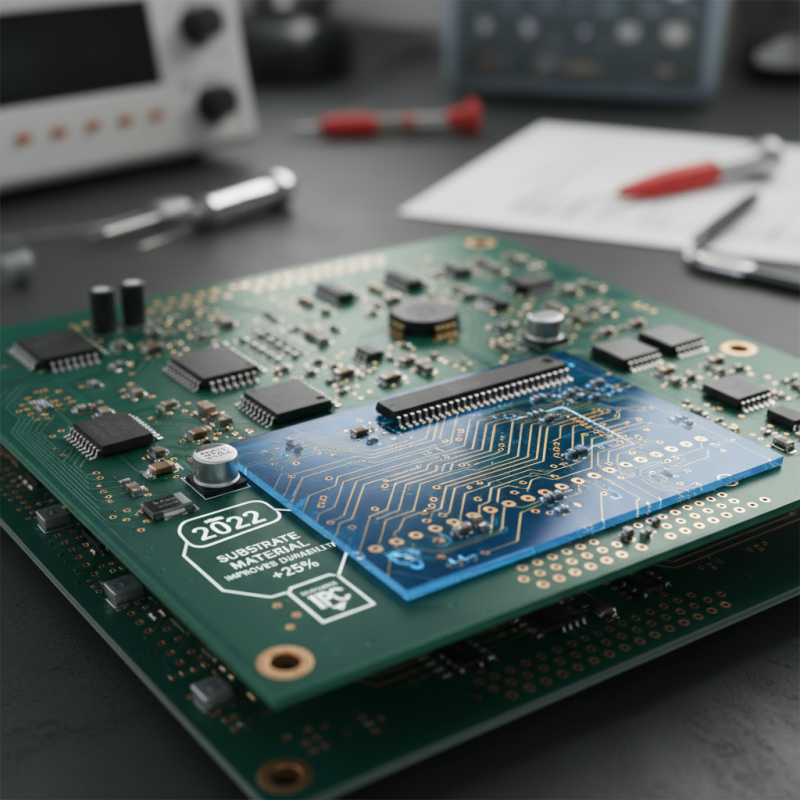

When assessing the quality and performance of printed circuit boards (PCBs), several key factors come into play. Firstly, material selection significantly affects the board's reliability and thermal performance. High-frequency applications, for instance, often require low-loss dielectric materials to minimize signal degradation. A 2022 report from IPC highlights that the choice of substrate material can impact not only the thermal management but also the overall lifespan of the PCB, with certain materials increasing durability by approximately 25%.

Additionally, the manufacturing process is crucial in determining the quality of PCBs. Techniques such as automated optical inspection (AOI) and X-ray inspection are now standardized in top-tier facilities, ensuring that defects such as solder voids or trace separation are identified and resolved promptly. A rigorous quality assurance process can enhance performance metrics, which are often evaluated based on metrics like yield rates and defect densities. According to a recent study by Research and Markets, companies that adopted advanced manufacturing technologies saw a reduction in defects by as much as 30%.

Tips: When selecting a PCB manufacturer, prioritize those that provide transparent quality metrics and robust testing protocols. Moreover, consider engaging with companies that are ISO-certified, as this indicates a commitment to maintaining high standards across all operations. Finally, staying abreast of industry innovations, such as the use of AI in quality control, can give you an edge in selecting the most advanced and reliable PCB solutions.

Innovative Technologies Transforming the PCB Manufacturing Landscape

The PCB manufacturing landscape is undergoing a remarkable transformation fueled by innovative technologies that are reshaping the industry. One of the most significant advancements is the integration of smart automation and robotics, which streamlines production processes and enhances precision. By minimizing human error and optimizing workflows, manufacturers can achieve higher output with shorter lead times. This shift not only increases efficiency but also supports the growing demand for complex PCB designs that require meticulous craftsmanship.

Another area of innovation is the adoption of advanced materials and nanotechnology. These new materials not only improve the performance and durability of PCBs but also enable the development of thinner, lighter, and more flexible products. This is particularly crucial in the electronics sector, where miniaturization has become the norm, and where high-speed performance is critical. The ability to create PCBs that can withstand extreme conditions while maintaining functionality is a game changer for industries ranging from aerospace to consumer electronics, paving the way for new applications and devices that were previously unimaginable.

Sustainability Practices in PCB Production: A Growing Concern

As the demand for printed circuit boards (PCBs) continues to rise, sustainability practices in their production have emerged as a significant concern for manufacturers and consumers alike. Companies are increasingly shifting their focus towards eco-friendly processes and materials that not only reduce their environmental impact but also cater to the growing awareness among consumers about sustainable products. This shift includes the adoption of recyclable materials, waste reduction practices, and energy-efficient manufacturing processes.

Tips: When evaluating PCB companies for sustainable practices, look for certifications related to environmental management, such as ISO 14001. Also, check if the company has clear policies on waste management and recycling programs.

Furthermore, incorporating sustainable practices can also drive innovation within the industry. By investing in research and development of green technologies, PCB companies can improve their production processes while minimizing ecological footprints. This not only helps the planet but can also enhance the desirability of their products in a market that increasingly values corporate responsibility.

Tips: Keep an eye out for companies that showcase their commitment to sustainability through transparent reporting. This includes sustainability goals, progress updates, and participation in industry-wide initiatives aimed at reducing environmental impact.

Top PCB Companies of 2025: Quality and Innovation

This chart illustrates the evaluation metrics for various key factors that are crucial for PCB companies in 2025. Metrics such as Quality Assurance, Innovation in Design, Sustainability Practices, Production Efficiency, and Customer Satisfaction reflect the emphasis on both quality and innovation in PCB production.

Future Trends in PCB Design and Manufacturing for 2025 and Beyond

As we look toward 2025 and beyond, several trends are emerging in PCB design and manufacturing that set the stage for innovation and quality. One significant trend is the increasing demand for miniaturization in electronics. According to a recent market report, the global PCB market is expected to grow at a CAGR of 5.2% from 2023 to 2028, driven by the proliferation of small, multifunctional devices. This necessitates the development of advanced materials and production techniques to create smaller, more efficient circuit boards.

Another focal point is the shift towards sustainable manufacturing practices. The PCB industry is increasingly being called upon to adopt eco-friendly processes, reducing toxic waste and using recyclable materials. Research shows that around 70% of companies in the electronics sector aim to incorporate sustainable practices by 2025, highlighting a collective industry movement toward greener solutions.

**Tip:** For manufacturers looking to stay ahead, investing in research and development to explore alternative materials can pay off. Additionally, adopting automation in production processes not only enhances efficiency but also reduces human error, ultimately improving the quality of the final product.

Finally, the integration of smart technologies in PCB design, such as IoT capabilities, is transforming how these components are conceived and deployed. As devices become smarter, PCBs must evolve to meet new performance demands. It's essential for companies to focus on flexibility and scalability in their designs, ensuring that they can adapt to future technological advancements.

**Tip:** Engaging in partnerships with tech innovators can provide invaluable insights into emerging technologies, enabling PCB manufacturers to stay competitive and relevant in a rapidly evolving market.

Related Posts

-

How Semiconductor Companies Are Shaping the Future of Technology Innovation

-

Understanding the Basics of Motor Control: How Your Brain Coordinates Movement

-

Exploring the Future of Electric Vehicles with Etel Motors and Industry Trends in Sustainable Transportation

-

What is the Best Electronics Tools for Every DIY Project

-

Why Motion Control Systems Are Essential for Modern Automation Solutions

-

Unlocking the Power of Etel Motion for Enhanced Digital Experiences